History

It has always been our goal to build a quality product that

exceeds other products in terms of quality, performance and

longevity. Today, after more than 15 years of experience, this

goal was reached, as the performance of our products shows.

We never stopped improving, although our compressors were ahead

of the competition from the beginning - but we focused on

details and still found opportunities to increase performance.

Even today, compressors of the first generation are still in use

- and wear and tear that would reduce efficiency could not be

noticed.

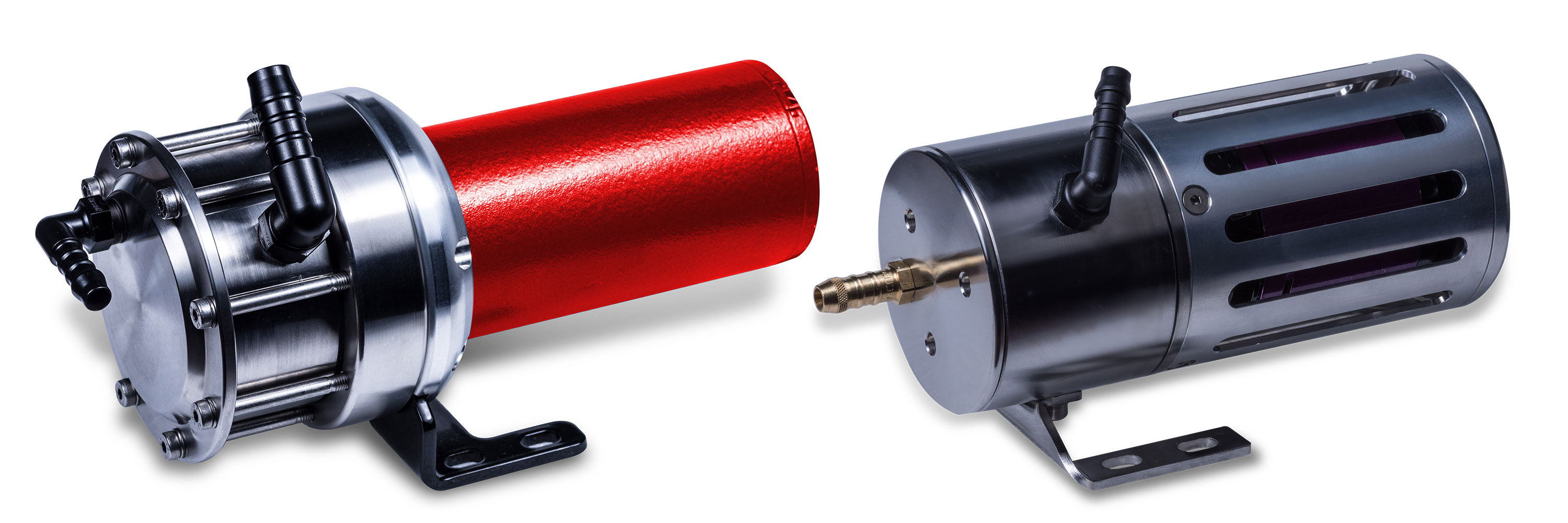

In 2012, the second generation was introduced to the market.

Those had increased performance and more variations were

offered. The 2nd generation Q-comps were unmatched on the market

– either as a compressor or vacuum pump.

And still - we didn’t stop improving. 2016 is the year of the

3rd generation! After one and a half decades we didn’t just

achieve another increase in performance, but our experience from

the markets went back into the design process. The result speaks

for itself: We reduced mass by more than 10 percent and

increased efficiency by introducing brushless technology.

And you can be sure, we will continue improving!